Handling and Conveyor Technology

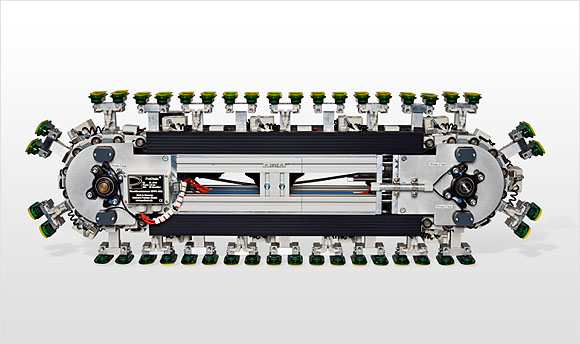

ProChain® - the Robot-Chain

ProChain® is an nnovative handling system that conducts electrical current and compressed air through the chain onto pneumatic grippers or vacuum suction cups / devices.

No empty return as linear axle or linear applications

No empty return as linear axle or linear applications

Low operating cost through increased efficiency

Low operating cost through increased efficiency

Significant increase in production (up to 75%)

Significant increase in production (up to 75%)

Exceptional capability (examble. 3000 pieces/min. at 60mm pitch)

Exceptional capability (examble. 3000 pieces/min. at 60mm pitch)

Key Benefits:

- Continuous or pulsed operation

- Modular, standardized assembly

- Configurable Function Design

- Fast possibility of adjustment for product change

- High rate of feedt up to 3m/s and high acceleration .depending on the product

- Arrive punctually switching with ASi-Bus at all speeds

- Products profile and material independent transported in all positions

- Any combined assembly possibilities of.Pneumatic, Sensoric and Electronic

- Virtually wear-and maintenance-free operation

- High flexibility

Operation

Circulating, intelligent chain system with energy as compressed air, electricity and data

Circulating, intelligent chain system with energy as compressed air, electricity and data

- Air pressure by rotary in the air pressure channel (up to 10 bar)

- Power supply (24 V DC) via slip ring contacts in line

- Data transfer via Asi-bus

Flexible execution of controlled functions at defined positions in circulation

Flexible execution of controlled functions at defined positions in circulation- Combined use of pneumatic products such as suction / gripper / cylinder

- Switching of actuators, solenoids, or e-drives

- Integrated sensors and signal transmission for monitoring functions

Applications

- Transport of various products regardless of what Surface / material / Geometry

- Positioning functions of collection, processing, packaging, etc.

- Stacking and unstacking

- Discharge / separation of parts

- Packaging applications for example Insert, Carton

- Palletizing e.g. Cartons, boxes

- Mount e.g. Paste, screws, mounting

- Printing

- Check e.g. Leak, visual inspection

Technical data:

- Output: 50 parts / sec or 3000 parts / min. (for example, at 60mm pitch, 40mm size pieces) other forms in consultation

- Max. speed: 2 - 3 m / s (target: 6 m / s)

- Conveyor Chain: Block or hinge chain

- Guideway: Roller or plain bearings

- Tracked: Standard: linear, curvilinear

- Chain pitch: Standard: 60 , 80, 100 mm or arbitrary

- Length: Optional chain division under

- Width: Standard 100 mm or in consultation

- Height: Depending on the chain division

- Mode: Continuous or pulsed

- Type of drive: Unlimited

- Protection: Up to IP65

- Control: ASi (A/B Slave´s, specification 2.1)

- Control interface: ASi bus coupler

- Max acceleration: In pulsed mode depends on the conveyed

- Repeatability: +/- 0,1 mm

- Ambient temperature: -5°C bis +50°C

- Operating pressure: 1 - 10 bar

- Pneumatic connection: Free choice, Flow-induced

- Air consumption: For each application

- Operating medium: Pressure air to the quality class DIN ISO 8573-1 Class 1-1-3

- Material: Aluminium, stainless steel or plastic

- Corrosion resistance: KBK class